About this deal

A supply of dry, clean and warm air or nitrogen is needed. It is important that the air is absolutely free of any oil content. Some adherent machine deposits require tactics that are more aggressive than a high-velocity flush, so you must match the flushing tactic and strategy to the problem you are trying to resolve with the flush. Once you understand the problem within the machine that needs to be cleaned, you can then select the appropriate flushing tactic to remedy it. This issue was described in Jim Fitch’s three-part series on flushing for Machinery Lubrication, which can be read at www.machinerylubrication.com/Read/609/oil-flush, www.machinerylubrication.com/Read/634/oil-flushing-tactics and www.machinerylubrication.com/Read/657/flushing-oil.

ENGINE FLUSHING. IS IT EVEN WORTH IT AND IF YES - Castrol

The pressure should be held to a minimum 3 to 5 bar (22 to 73 psi), measured downstream from the flushing circuit, before the return line filter and sampling port. Cleaning of ball, plug, butterfly and needle valves is an important part of the hot flush process. To ensure cleanliness has been reached in all zones, the hydraulic valves should be actuated to full-stroke movement during each step of the cleaning process. The importance of having a clean engine cannot be understanded, so any product which tries to actively clean the engine’s moving parts is clearly well intended. But, using a product manufacturers do not recommend is always a risk, especially when it comes to something you can see in front of you.use engine flush only after warming the engine to its working temperature. After adding Engine Flush(EF), let it idel for 10-20 minutes. Contaminants circulating throughout the engine can lead to oil breakdown and increased viscosity – and higher-viscosity oil requires more energy to circulate throughout the engine. Just because the changeover has been completed does not mean that you are “out of the woods.” Your system will need to be closely monitored for a while to make certain that the flushing was thorough. Taking the time to verify that the system is fully flushed and purged of the old fluid prior to introducing the new fluid will go a long way toward ensuring a healthier hydraulic system. A newly fabricated system or one that is in-service requires different approaches for when and how to perform flushing. This is because of different procedural methods deployed, but more so because of practical limitations and overall requirements of individual machines. It is important to consider that flushing can become time-consuming, and it may be difficult to predict the time needed to do so. Ten percent of the old contaminated or depleted lubricant may be enough to use up most of the additives of the new oil.

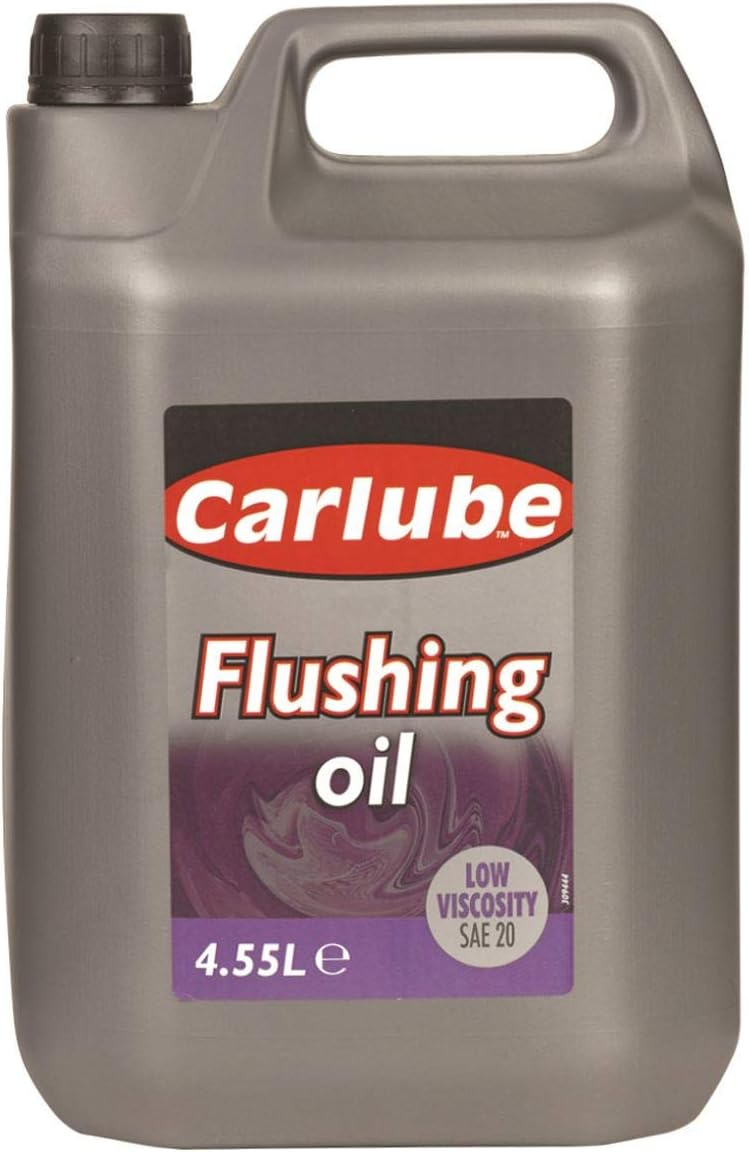

Flushing Oil | Pennine Lubricants

NOTE: If components contain anticorrosion agents not compatible with the system fluid, flush the components using system oil with 5 to 10 percent degreasing agents added to the flushing fluid. The degreasing agent should be selected to ensure no harm to component seals. Soils may be mechanically or chemically removed. Flushing is a type of high-pressure, high-flow fluid circulation used to generate physical movement of contaminants. As the pressures/flow is used for flushing, circulating clean fluid in the system cannot clean rust and scale from the piping, deburr machined elements or remove flux or weld slag. After the 20m are up, you have to change the oil and filter. To not contaminate the new oil with the remaing old oil and ef, you should first drain old oil and add new and cheap oil and let the car idle for another 10 minutes. After that do a propper oil change with the prefered oil brand and new oil filter. The filter system should have sufficient capacity and performance to remove both solid particles and moisture to the required level, within a reasonable time. The flushing procedure depends on the specifics of machinery, plant conditions and flushing equipment. To obtain the best results, follow these guidelines:Select suitable system filters. New oil should be filled through a system filter or another suitable filter. While these are the usual circumstances when a flush should be used there are also instances where a flush should be performed between oil changes. Here are a couple of guidelines on when flushing should be done between oil changes:

Flushing Oli Pakai Teknik Ini, Modal Dikit Daleman Mesin Flushing Oli Pakai Teknik Ini, Modal Dikit Daleman Mesin

Leakage and seal problems - when new chemistry is added to a machine and/or a violent flushing occurs, seal performance may be affected. This may also be due to changes in lubricant viscosity or interfacial intension from fluid mixing problems. Components that restrict the flow rate, and thereby increase the pressure drop, should be isolated from the flushing circuit and cleaned individually. Example: a hydraulic system has a flow rate and tube diameter to achieve Re=3,400 in normal service. Flushing requires a minimum of Re=4,080.

Power flushing - A variation of recirculation, where the oil level in the sump is reduced and a high-velocity fluid is applied to mechanically dislodge, lift and entrain particulate debris. Power flushing suspends and transports particles; absorbs air, chemical products and water from the system; and releases the contaminants to a filter. If low-temperature contamination is found, it should be removed via the engine and oil through prolonged engine use at normal oil operating temperature (~90°C). If such engine operation is not possible, it is recommended to use Castrol Engine Shampoo – a flush that will dissolve contamination within 10 minutes of idling. The contaminants can then be removed during the oil change (right after the flushing process). Reoccurrence of this type of contamination can happen if the vehicle is constantly driven with underheated oil (short distances/urban conditions) or if engine failure occurs (e.g. coolant penetrating into the engine). Deposits and sludge build up in the engine for several reasons, one of the most common of which for most drivers is frequent short journeys. Taking a lot of short trips and stop and go driving is surprisingly hard on the lubricating oil because moisture that builds up in the oil during the previous rest period won’t have time to evaporate and leave the oil. This means the oil becomes diluted and increases viscosity and in the end it doesn’t lubricate the moving parts of the engine as well, leading to increased wear.

Great Deal

Great Deal